Saving Time and Money

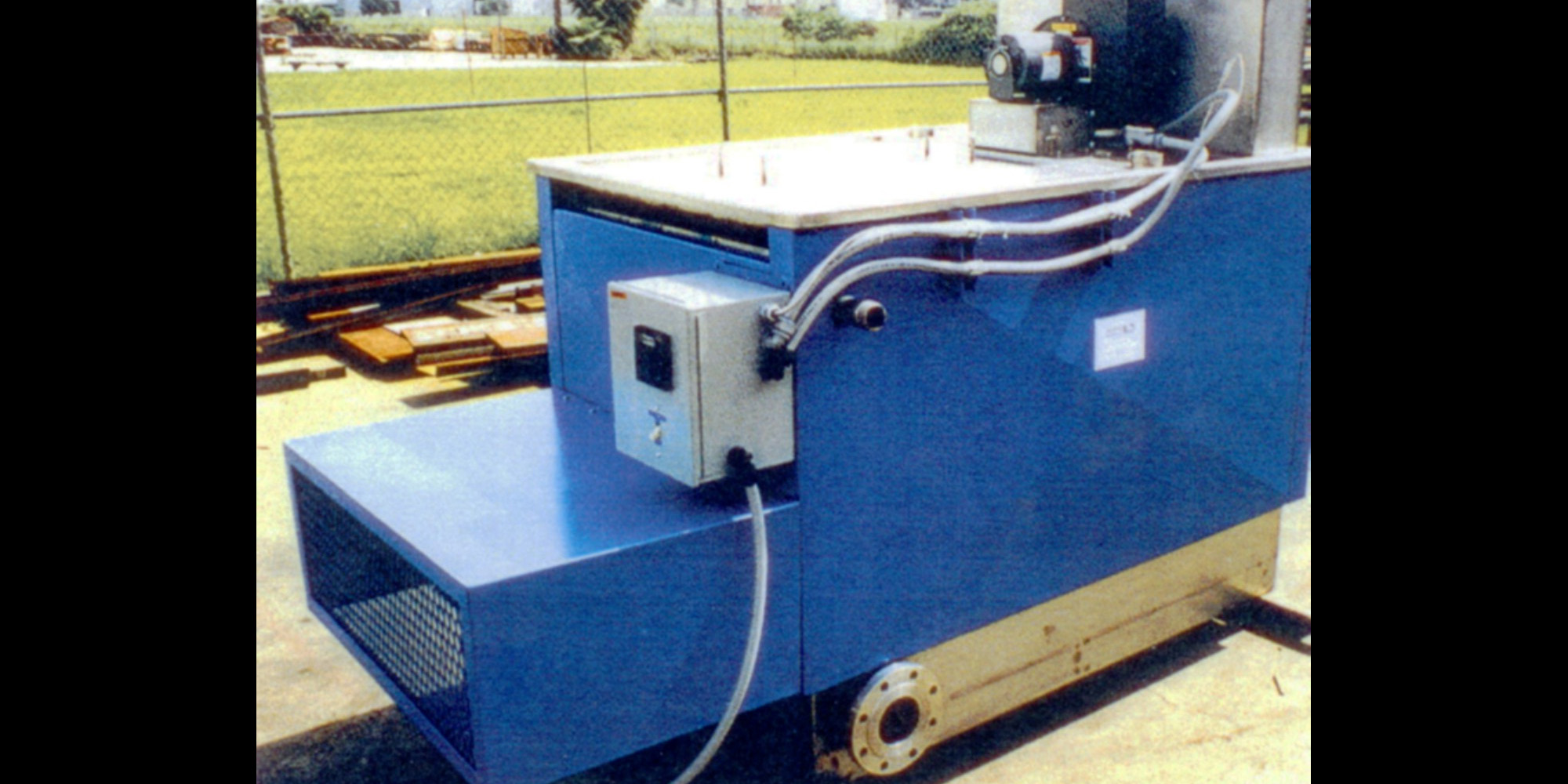

Disposing of liquid waste through traditional means can be time-consuming and expensive. Evaporators from CJI Process Systems offer a convenient and practical solution. CJI manufactures and sells our own line of standard evaporator systems, as well as custom configurations for those needing more tailored applications.

CJI’s evaporators convert the water contained in aqueous waste into water vapor, while segregating solids and oils into a sludge that can be disposed of through approved channels. By reducing the volume of effluent, CJI evaporators can help to significantly cut operating costs while opening up environmentally acceptable disposal options.

Many Applications

Customers use our water evaporators for many different applications where disposal of aqueous solutions is an issue. Some of these include:

- Die-Casting Solutions

- Hydrotesting Solutions

- Mop Waters

- Phosphating Solutions/Rinse Waters

- Plating Solutions/Rinse Waters

- Water-Based Cleaners/Rinse Waters

- Dye-Penetrant Rinse Waters

- Machining & Grinding Coolants

- Oily Compressor Waters

- Photographic Solutions

- Tumbling & Vibratory Solutions

- Wire Drawing Compounds

Energy-Efficient CJI Evaporator Systems

As leading experts in water evaporator design and construction, CJI has fine-tuned our proprietary approach to manufacturing the most energy-efficient water evaporators on the market. CJI evaporator systems are designed to minimize heat loss, preserving BTUs for evaporation. Maximizing operating efficiency gives CJI evaporators an appreciable cost savings compared with other evaporators. Most fuel types/heat sources can be used, including gas, electric and steam.

Standard Design Available

The CJI Process Systems “standard” gas-fired evaporator offers customers our tested and standardized system concept in any size and capacity to meet their specific needs. As one of the most energy-efficient evaporators available, the CJI Model 1514 typically has less than a 5 percent heat loss, compared with most other “lightweight” systems that lose up to 14 percent of their heat. Overall, this represents a significant cost savings with the CJI system.